About us

My name is Sylwester Jabłoński and I am the founder and owner of Parkiety Jabłoński . In our family, the love for wood has been passed down from generation to generation for over 140 years. This passion inspired me to found a company specializing in creating floors from the noblest species of wood . For almost 30 years of operation , combining our experience with modern trends, responding to the needs of even the most demanding customers . We always focus on the highest quality and innovation . , as evidenced by the path that we , together with the entire team, have traveled over the last three decades. , we do not stand still and boldly plan the next steps on our development path .

We'll soon see what "Tomorrow" brings

February 8, 2019

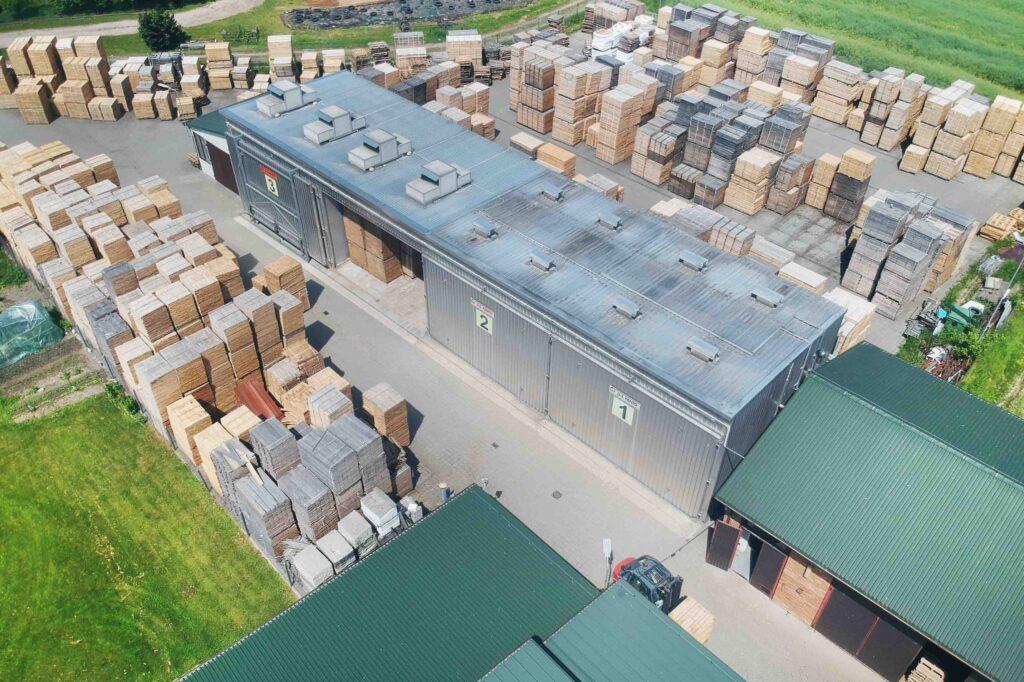

Changes, changes and once again development…. Since we built additional dryers and increased our capacity, the appetite of our customers has also increased. To meet their expectations, we built another hall and purchased the latest machines from the German manufacturer Schroeder. Thanks to new possibilities, we are able to continue to develop and produce much larger quantities without losing the quality of the floors we produce.

April 3, 2015

Among the remaining machines, there will be additional 6-head machines, which allow us to final process wood even more precisely.

January 14, 2015

C

Part of our team helps create an educational film for new generations of carpenters. We are happy to share the knowledge we acquire through our many years of practice.

April 16, 2014

On this day, we officially received the FSC 100% certificate.

This certificate is awarded to organizations that obtain raw materials for the production of products from forest areas where responsible forest resources are managed and social and labor rights are respected. This certificate confirms that the wood we buy comes from legal sources, and the raw material we purchase is replaced by young seedlings that will replace their predecessors in the future.

October 18, 2013

From that day, the CE mark is printed on Flooria boards leaving our production line, next to the logo and serial number, confirming the product's compliance with the European standard. The entire print appearing on each board is our company's assurance of the care with which each board was manufactured by us. Thus, we sign with both hands the quality of our products.

October 1, 2011

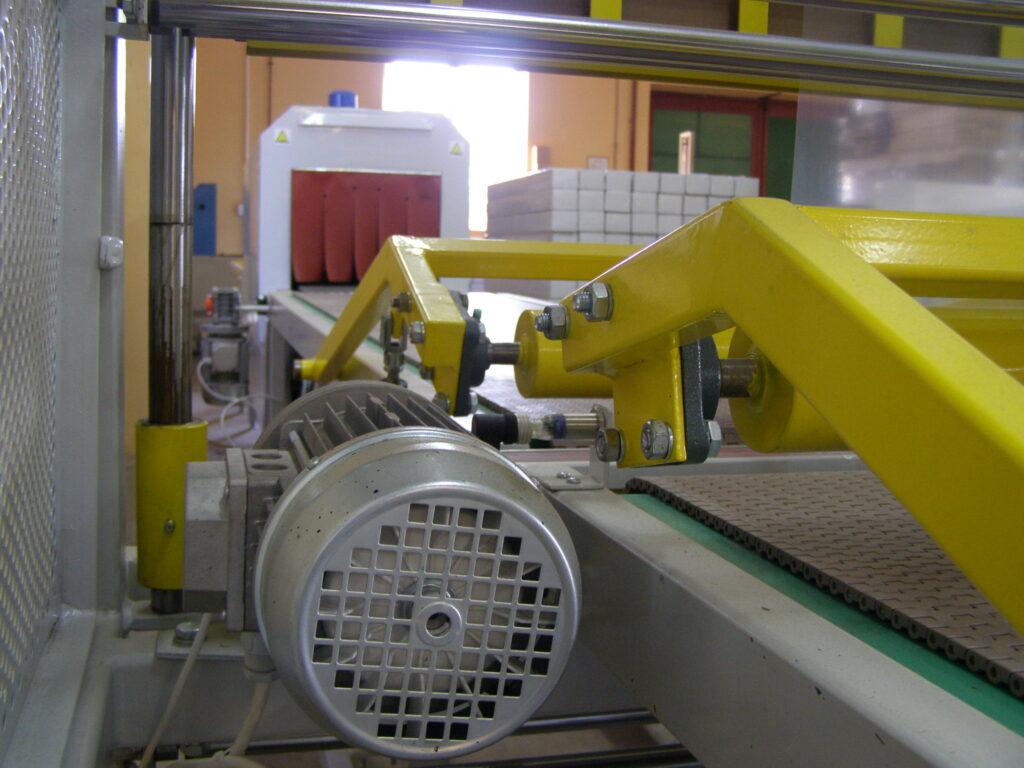

Great interest in our products and continuous development of production encouraged us to purchase and launch a new, more efficient packaging line.

The surfaces of the finished boards are protected against damage with a special sponge. For mechanical protection, they are packed in cardboard packaging and for insulation from external factors, additionally in heat-shrinkable foil.

September 30, 2010

Registration of the Flooria trademark.

Official start of production of Flooria boards. A whole range of boards with a finished surface is produced under this name. Our offer includes stained and natural-colored boards, finished with UV varnishes and natural oil waxes.

September 27, 2010

Launch of a paint shop with a modern painting line.

A very important event in the history of the company and a milestone in its development.

From now on, we can expand our offer with boards with a finished surface. The launched painting line is the SmartParquet line from the Italian company Cefla (Sorbini). It is intended for applying UV varnishes and natural oils. The line works together with a grinder from Costa, also Italian. This tandem, combined with Chimiver varnishes, allows us to obtain a varnish surface that our customers consider to be unique from other products.

April 24, 2010

Launch of the second of two planned drying plants with a computer control system. This is the fourth chamber in the company.

At the same time, the control system in two older chambers was replaced, thanks to which all chambers were connected to one centralized computer system. From that moment on, we have the ability to remotely supervise all chamber processes. This is a great comfort for our company, because thanks to it we monitor the operation of the dryers that prepare subsequent batches of materials 24 hours a day, 7 days a week.

December 9, 2009

Launch of a modern dust removal system.

The existing set of filters was replaced with a new, more efficient and energy-saving central dust removal system connected to an automatic fuel feeding system to the furnace, which significantly improved waste management.

October 9, 2009

Commissioning of a new boiler room.

Growing production and storage spaces and the planned expansion of further drying rooms prompted us to modernize the heating system. A fully automatic wood waste furnace was installed with more than twice the power of the previous one.

March - August 2009

Opening of a new, expanded production hall and construction of warehouses.

After five years, the old hall became too narrow and it had to be expanded. There was also a lack of storage space, which was increased almost three times by building a completely new warehouse building equipped with devices allowing for indoor climate control. Thanks to this, our products are stored in the most convenient conditions possible.

December 6, 2008

The development determined the need to employ new office workers and divide the administration into specific departments, which in turn resulted in the need to expand the office space.

October 11, 2008

Launching a high-temperature steaming plant for thermal modification of wood.

Our offer includes thermo ash floors in two colors: amber and cognac, some time later, the Antyk Natur version of Oak is added to the Termo wood offer.

We are one of the first companies in Poland to have our own chamber of this type, which is why today we are one of the more experienced in thermowood processing.

August 18, 2004, March 12, 2005

Launching two dryers with a fully electronic, programmable and automatic drying process control system. The software reads the measurements of the changing wood humidity and the climate inside the chamber and independently introduces changes in individual stages of the previously introduced drying program.

August 3, 2003

Construction of the first production hall.

The current production is moved from several farm buildings under one roof of the new hall. In addition, the old office is replaced with a new room next to the production hall.

August 16, 2000

Relocation of the sawmill part of the plant to Bujały.

From the beginning, our floors were produced not from semi-finished products, but from round wood brought straight from the forest. Thanks to this, we can be sure of the origin of the wood and the quality of the raw material. So far, both raw and final processing took place in one place. However, the need for development forced the division of the organizational structure into two separate but dependent stages: wet processing and final processing.

August 27, 1998

Purchase of the first forklift.

A milestone in history and a symbol of the transition from the mentality of a small craft workshop to a production plant.